Scaling Your Automation Strategy with System Integration Solutions

Written by Automation Services Inc. | read

Adapting to evolving demands in manufacturing requires strategies that enable growth without causing disruptions to ongoing operations. One such strategy is scalable system integration, which allows manufacturers to expand their automation capabilities in a forward-thinking, cohesive way. This approach focuses on integrating modular, flexible, and future-proof solutions that can be easily updated or scaled as requirements change. By doing so, manufacturers can stay ahead of technological advancements, meet industry standards, and adapt to shifting customer demands while maintaining maximum efficiency and minimizing downtime. Scalable integration ensures that businesses are not just keeping up but are also prepared for future growth and challenges.

The Need for Scalability in Modern Manufacturing

The manufacturing landscape is constantly changing, driven by technological advancements, fluctuating consumer demands, and global competition. Scalability has become a central requirement for businesses aiming to stay competitive.

Manufacturers need solutions that grow with them, accommodating increased production capacity and new technologies without overhauling existing systems. Scalable system integration makes this possible by enabling seamless expansion as operations grow. Without scalability, plants risk downtime, inefficiencies, and high retrofit costs when attempting to meet rising demands.

These are the key benefits of scalability in manufacturing:

- Supports business growth without disrupting workflows.

- Ensures smoother adoption of new technologies.

- Reduces costs associated with system redesigns and inefficiencies.

Role of System Integration in Expansion

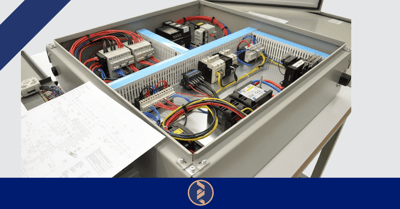

When scaling operations, disjointed systems can hinder progress and lead to costly inefficiencies. This is where scalable system integration plays a vital role. By linking hardware, software, and processes, system integration creates a unified infrastructure that supports seamless growth.

Integrated systems ensure that all machines, devices, and operational processes work together harmoniously. For example:

- A centralized data platform allows all departments to access production metrics, improving decision-making.

- Integrated robotics and automation streamline repetitive tasks, reducing operational bottlenecks.

- Predictive maintenance systems, linked to other production components, minimize downtime by addressing potential failures proactively.

Through these solutions, manufacturers create an ecosystem that adapts as they scale, fully supporting their automation growth strategy.

Modular Design for Long-Term Flexibility

One of the key elements of building scalable systems is adopting modular automation. Modular designs break larger systems into smaller, independent components. These components can be easily added, updated, or replaced without disrupting the broader system.

Why modular design matters:

- Flexibility: Manufacturers can adapt to market changes by upgrading or replacing specific modules instead of redesigning entire systems.

- Cost Savings: Modular components simplify repairs and upgrades, which lowers expenditures.

- Speed: Modular automation accelerates deployment and streamlining of systems.

For example, a packaging plant might integrate modular conveyor systems that can be extended or reconfigured based on changes in product packaging requirements. This approach ensures long-term operational agility, positioning manufacturers to remain competitive in their respective industries.

Integration Tools that Support Growth

Growth in automation requires reliable tools to facilitate both integration and scalability. These tools function as enablers, ensuring that processes remain connected and data flows uninterrupted.

- Industrial Internet of Things (IIoT) platforms allow seamless real-time data sharing across machines, enabling smarter operations.

- Advanced SCADA (Supervisory Control and Data Acquisition) systems ensure centralized monitoring and control of machinery.

- APIs (Application Programming Interfaces) enable the connection of various software platforms, creating streamlined communication between ERP, MES, and production systems.

These tools are vital for expanding the capabilities of a factory floor while aligning with an overarching automation growth strategy.

Additionally, investing in analytics software can make growth more strategic. Predictive analytics tools, for instance, help identify future trends or challenges, allowing manufacturers to adjust production plans before issues arise.

Partnering for Scalable Solutions

Building a future-ready automation ecosystem requires expertise and experience. To ensure success, choosing the right partner for scalable system integration is essential. The ideal partner brings industry know-how, cutting-edge technology, and proven methodologies to the table.

Partners can help by:

- Designing and implementing future-ready systems tailored to specific operational goals.

- Offering modular solutions to minimize future upgrade complexities.

- Providing ongoing support and system enhancements to keep businesses competitive.

Collaborating with a thought leader in automation and integration ensures that businesses are equipped to face challenges and seize opportunities in a fast-changing market.

ASI Helps Companies Grow Smarter

Expanding your manufacturing capabilities doesn’t have to mean disrupting current operations. With ASI, you can access expert support to implement scalable system integration and create future-ready systems. Modular solutions keep your production line flexible, while our tailored approach ensures seamless integration into your automation growth strategy.

Start building your long-term automation success today. Partner with ASI to future-proof your manufacturing systems and scale intelligently. Let's build a system that adapts to your vision without limits. Reach out now to explore your options!