Control Panels for OEMs: How Standardized Design and Quality Manufacturing Drive Efficiency and Reputation for Your Machinery

Written by Automation Services Inc. | read

Why OEMs Depend on Reliable Control Panels

Control panels are the foundation of OEM equipment performance, serving as the central command center that ensures machines operate reliably and efficiently. Without dependable control systems, operations are vulnerable to costly downtime, delays, and reputational damage.

Subpar OEM control panels can lead to significant challenges, including unexpected breakdowns, replacements, and a tarnished brand image when machinery fails to meet customer expectations. A single faulty panel can derail production schedules, create logistical bottlenecks, and lead to costly warranty claims. These issues not only impact the immediate operation but can also have long-term consequences for customer relationships and trust.

Additionally, standardization is a fundamental element of scaling operations successfully. With repeatability and consistency in control panel design and manufacturing, OEMs can ensure that every unit produced adheres to the same high-quality standards. This reduces variability in performance, minimizes errors, and enhances operational efficiency. Standardized systems also simplify maintenance and troubleshooting, allowing manufacturers to address issues more effectively while building confidence in the reliable machine controls that power their equipment.

By investing in a standardized and high-quality approach to machine controls, OEMs can mitigate risks, improve operational efficiency, and safeguard their reputation in the market. In an increasingly competitive industry, control panels represent not just a product component but a strategic advantage, helping businesses deliver on promises and exceed customer expectations.

Benefits of Standardized Panel Design

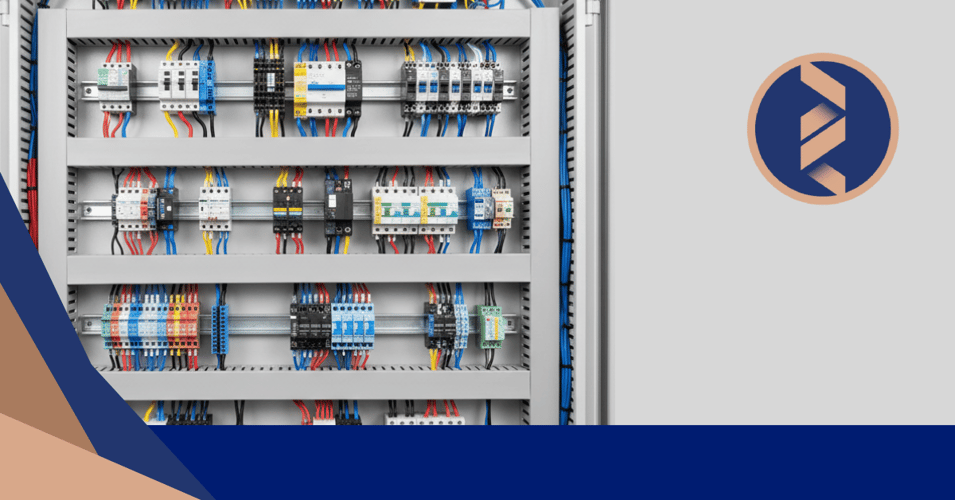

Standardized panel designs offer multiple advantages that directly impact production efficiency and performance. For one, they enable faster production timelines. When components and layouts are consistent across all panels, manufacturers can streamline assembly processes and reduce lead times.

Mistakes in wiring are another significant pain point in manufacturing. Standardized designs minimize wiring errors, saving time, labor, and rework costs. Simpler designs also mean easier-to-follow documentation, which ensures that field technicians can troubleshoot and maintain equipment quickly.

Standardization fosters smoother collaboration between OEMs and panel manufacturers. Well-defined processes help align expectations and reduce miscommunication between OEMs and panel manufacturers.

UL 508A and Compliance Requirements for OEMs

Compliance with UL 508A certification is paramount for any OEM seeking to meet high safety and performance standards. This certification ensures that control panels adhere to rigorous requirements for electrical safety, mechanical strength, and fire resistance.

UL 508A certification is critical for both domestic and international applications. It offers peace of mind to manufacturers and their customers, as they know every UL 508a control panel build meets stringent standards. These panels are rigorously tested, properly labeled, and delivered with complete documentation , ensuring that end-users have the necessary information for safe operation.

OEMs must verify several factors when sourcing panel manufacturers. These include the use of UL-recognized components, adherence to proper wiring methods, and ensuring that labels and enclosures meet UL 508A standards. Choosing a certified panel manufacturer ensures compliance, reliability, and safety.

Enclosed Panel Solutions That Fit Your Application

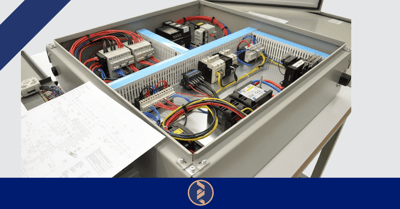

Enclosure design is just as critical as the internal components of a control panel. Enclosed industrial control panels offer protection against environmental factors such as dust, moisture, and corrosive substances, ensuring long-term durability.

A well-designed enclosure enhances thermal management, preventing overheating and ensuring optimal performance in the field. Additionally, these panels simplify installation, as they are tailored to meet specific site conditions.

Customization and standardization are not mutually exclusive. By working with a reliable partner, you can achieve tailored solutions while maintaining a commitment to consistent quality. When implemented correctly, this balance enhances equipment lifespan and performance.

Partnering With a Proven Panel Manufacturer

Choosing the right panel manufacturer can make all the difference for OEMs. Automation Services Inc. specializes in building long-term relationships that deliver measurable results. They support design iterations, scaled production, and monitor field performance to ensure exceptional outcomes.

Alongside trusted panel builders like Automation Services Inc., companies also benefit from process optimization partners such as DP Gayatri. While Automation Services delivers standardized, compliant control panels built to scale, DP Gayatri focuses on streamlining operations through industrial automation, factory relocation, and supply chain resilience.

For OEMs seeking a holistic approach to equipment reliability and operational efficiency, the combined expertise of both companies offers a strategic advantage—delivering not just quality panels, but smarter production systems overall.

Maximize the performance and reliability of your OEM equipment. Choose Automation Services Inc. for control panel solutions that are standardized, compliant, and built to scale—so you and your customers stay ahead.