Custom UL 508A Enclosed Industrial Control Panels & Features

Written by Automation Services Inc. | read.png?height=500&name=Beyond%20Standard%20Panels_%20Customization%20and%20Advanced%20Features%20in%20Enclosed%20Industrial%20Control%20Panels%20(UL%20508A).png)

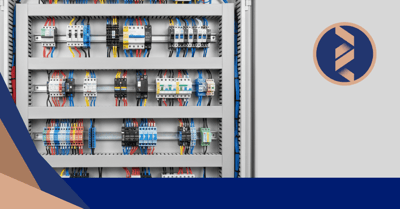

Today’s industrial systems demand more than just basic electrical control panels. Enclosed industrial control panels have evolved to meet the growing complexities of manufacturing, energy, and automation sectors. With certifications like UL and cUL 508A ensuring safety and consistency, customization has become crucial to address specific operational needs. This article explores why customization matters, highlights advanced panel features, and offers guidance on selecting the right components and manufacturers.

What Is an Enclosed Industrial Control Panel?

An enclosed industrial control panel is a system that houses electrical components—such as relays, circuit breakers, and overload devices—within a protective enclosure. These panels are designed to efficiently manage, control, and interface with industrial equipment.

Understanding UL and cUL 508A Compliance

UL and cUL 508A are safety standards that certify panels and their components for compliance with nationally recognized safety requirements. A UL/cUL 508A-certified control panel ensures that the system can operate across a wide range of environmental conditions while meeting stringent safety, wiring, and labeling requirements. When planning an ul cul 508a control panel build, it’s essential to follow these standards to guarantee both safety and functionality.

Standard Features in Compliant Panels

UL-compliant control panels typically include features such as:

- Clearly labeled internal components

- Short circuit current ratings (SCCR) to ensure safety during faults

- Adequate ventilation to regulate operating temperatures

These features form the baseline for building high-performing panels.

When Standard Panels Aren’t Enough

While basic control panels are suitable for many applications, they often fall short in complex or highly specialized environments.

- Limitations of Off-the-Shelf Solutions: Standard, pre-designed panels often fail to accommodate unique operational needs such as specialized equipment, complex system integration, or harsh environmental conditions—resulting in inefficiencies and unexpected downtime

- Benefits Of Customization: That’s where custom industrial control panels come in. Custom designs enable seamless integration into broader systems, offering enhanced functionality, better connectivity, and a solution tailored to your operation’s exact needs.

- Panel Adaptability: Adaptability is another key advantage of customized panels. Custom panels offer greater flexibility, enabling a smoother integration into highly automated systems where components like Human-Machine Interfaces (HMIs) and Programmable Logic Controllers (PLCs) must function in unison.

Advanced Features That Enhance Panel Functionality

Forward-thinking manufacturers are increasingly adopting control panels with advanced panel features (HMI, PLC, VFD, etc.) to enhance efficiency, system monitoring, and performance control.

Integration of Advanced Components

An advanced panel includes technologies like HMIs, PLCs, and Variable Frequency Drives (VFDs). Together, these components enable greater automation precision and operational control, optimizing the entire machinery workflow.

HMI integration provides operators with visual interfaces for monitoring and control.

PLCs process complex control commands that improve automation efficiency.

VFDs manage motor speeds, enhancing energy efficiency and reducing wear on equipment.

Intuitive Diagnostics and Remote Access

Beyond their physical features, advanced panels enable smarter control. Built-in diagnostics, condition monitoring, and remote access capabilities enable predictive maintenance and real-time system adjustments—minimizing downtime and enhancing responsiveness.

Industry Applications

These innovative features have applications in industries like automotive manufacturing, food production, and energy systems. For example, incorporating features like HMIs, PLCs, and VFDs into an automotive assembly line can reduce operational delays and improve quality control through more precise automation.

Selecting the Right Industrial Automation Components

Selecting the right components is critical to the overall performance and scalability of your control panel system.

Role of Components in Scalability

High-quality industrial automation components ensure that a panel can grow with your system’s needs. For instance, modular designs allow for future upgrades without complete overhauls.

Impacts on Cost and Availability

The right components also influence cost-effectiveness and system reliability. Recognizing the trade-offs between initial costs and long-term serviceability is critical when sourcing parts.

Importance of Product Compatibility

Working with a supplier experienced in industrial automation components ensures that all elements are compatible, reducing the likelihood of costly errors during installation or operation.

-png.png?width=527&height=469&name=Selecting%20the%20Right%20Industrial%20Automation%20Components%20-%20visual%20selection%20(2)-png.png)

Why Work With a Specialized Panel Manufacturer

Partnering with a specialized manufacturer is essential for ensuring compliance, functionality, and long-term reliability.

The Value of Expertise

A specialized manufacturer offers expertise across mechanical, electrical, and software disciplines. They manage the nuances of compliance management and handle documentation, such as certification and testing reports.

Field-Tested, Tailored Solutions

Companies like Automation Services Inc. provide project-ready and field-tested panels designed to function precisely as required. Their approach ensures not only compliance with standards like UL cUL 508A control panel build but also the creation of durable, efficient systems tailored to specific applications.

Final Insights

In today’s fast-paced industrial landscape, selecting standards-compliant, field-validated, and custom-engineered control panels is not just a best practice—it’s a critical factor for operational excellence. Collaborating with seasoned experts like Automation Services Inc. ensures your systems align with regulatory requirements, deliver optimal performance, and scale seamlessly with your facility’s growth.

Ready to upgrade your control infrastructure? Visit Automation Services Inc. to explore how their tailored solutions and decades of experience can help you design smarter, safer, and more adaptable automation systems. Let their team turn your complex project requirements into reliable, future-ready performance.