Key Elements of an Effective Electrical Control Design in Automation

Written by Automation Services Inc. | read

Efficient electrical control design is the backbone of modern automation systems. It determines how industrial equipment operates, communicates, and maintains consistent performance. Whether you’re designing control system design solutions for a manufacturing floor or programming cutting-edge robotics, understanding the principles of robust electrical control panels is crucial.

This article explores the critical components of an effective electrical control design, highlighting essential elements, safety considerations, and common pitfalls. You’ll also learn about relevant tools and how to apply automation wiring best practices.

What is Electrical Control Design?

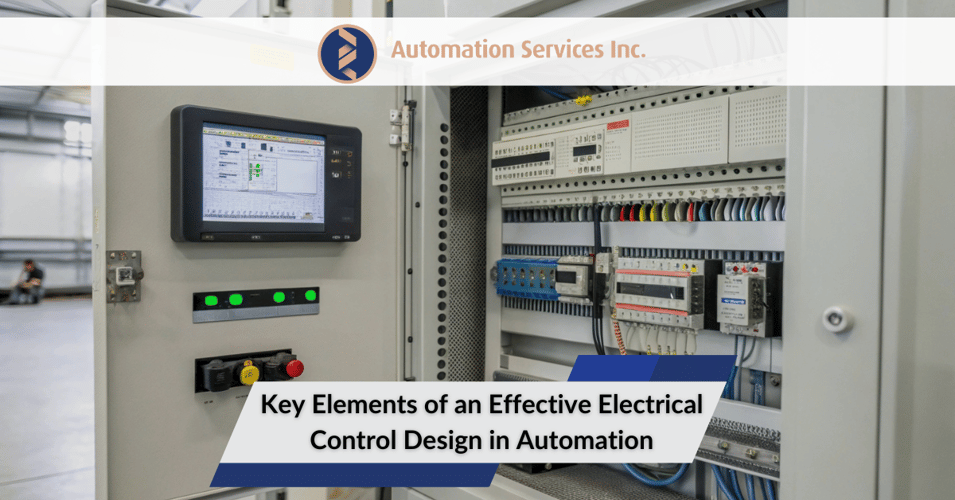

Electrical control design refers to the process of creating and organizing the systems that power, monitor, and automate machinery. It encompasses selecting hardware, wiring, logic design, and ensuring seamless integration between components like controllers, sensors, and actuators.

Simply put, it’s the blueprint behind anything automated. From the placement of electrical control panels to the sophistication of control panel layout, control design ensures machines run precisely as intended. This includes logic development through programmable logic controllers (PLCs), human-machine interfaces (HMIs), and SCADA systems to facilitate operation and monitoring.

A well-thought-out design saves time, reduces operational downtime, and boosts safety standards, making it a critical focus for engineers working in automation.

Core Elements of a Robust Design

Building a reliable control system design requires attention to these foundational elements:

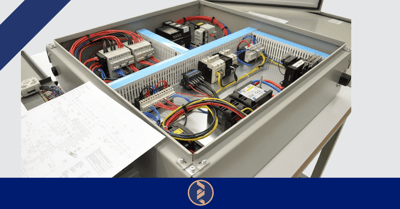

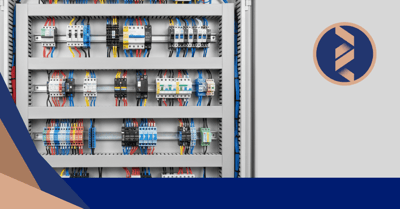

- Accurate Component Selection

Choose components that match the requirements of your system, including controllers, circuit breakers, power supplies, and relays. Each component plays a role in ensuring smooth operations. - Thoughtful Control Panel Layout

Proper control panel layout ensures easy accessibility during maintenance while improving airflow and reducing the chance of overheating. Group related components logically, and clearly label every connection. - High-Quality Wiring

Follow automation wiring best practices, such as proper cable management, avoiding cable interference, and using shielded cables where needed. This minimizes errors and ensures the system’s long-term reliability. - System Redundancy

Include fail-safes and backup power sources in the design to maintain operations during hardware failures or power outages. - Comprehensive Testing

Before commissioning, thoroughly test the design logic, wiring, and functionality. Regular testing during the design stage helps catch faults early.

A robust electrical control design isn’t just technically sound but also user-friendly, prioritizing ease of maintenance and long-term reliability.

Safety and Standards Considerations

Safety should never be an afterthought when designing electrical control panels for industrial automation. Following global and local safety standards is essential to protect both equipment and personnel.

- Adherence to Standards

Familiarize yourself with standards like IEC 60204-1 and NFPA 79 for electrical machinery safety to ensure your designs comply with industry benchmarks. - Installation of Safety Devices

Integrate circuit breakers, emergency stop buttons, surge protections, and lockout-tagout mechanisms for enhanced workplace security. - Grounding Practices

Improper grounding can damage components and endanger operators. Always follow best practices for grounding within a control panel layout. - EMI and Noise Reduction

Design systems to withstand electromagnetic interference and reduce noise. Shielded Ethernet cables and ferrite beads are beneficial tools. - System Documentation

Provide operators with easy-to-read guidelines, emergency procedures, and maintenance instructions to avoid accidents.

Implementing these considerations directly reduces risk while maintaining optimal functionality under varying operating conditions.

Common Mistakes to Avoid

Even skilled engineers may overlook details during control system design. Here are frequent mistakes to watch out for:

- Overcrowded Control Panels

Packing too many components into a panel not only complicates maintenance but increases the chance of overheating. Prioritize efficient control panel layout and adequate spacing. - Improper Wiring Practices

Ignoring automation wiring best practices, like improper crimping or using undersized wires, can lead to failures. Always use high-quality materials and follow wiring standards. - Forgetting Documentation

Disorganized or incomplete documentation confuses troubleshooting and makes updates harder. Standardize your documentation and organize it effectively. - Neglecting Scalability

Plan for possible system expansions. Leave space for future additions within electrical control panels, and ensure components can be upgraded if necessary. - Skipping Simulations

Failure to simulate system behavior before implementation can result in expensive, time-consuming on-site corrections. Use simulations extensively during the planning phase.

By addressing these problems early in the design process, you can save time, resources, and prevent headaches down the road.

Tools for Control Design

Modern tools make design simpler and more precise. Here are some essential solutions to consider:

- Computer-Aided Design (CAD) Software

Programs like AutoCAD Electrical and EPLAN are popular for creating detailed wiring diagrams and control system design schematics. - Simulation Software

Tools like MATLAB enable designers to run system simulations to ensure operational accuracy before installation. - Programming Tools

Use IDEs specific to your controller brand (e.g., Siemens TIA Portal or Rockwell Studio 5000) for writing and testing logic programs. - Wire Labeling and Management Tools

Organize and label every cable, adhering to automation wiring best practices, to simplify future troubleshooting.

Investing in the right tools pays dividends by streamlining every stage of the design process.

Learn How ASI Can Help You Apply These Design Principles to Create Safer, Smarter Systems

Designing effective electrical control panels for automation requires deep technical knowledge, precise execution, and access to the right tools and expertise. At Automation Services Inc. (ASI), we specialize in comprehensive control system design and control panel layout, applying industry-recognized best practices to deliver automation solutions that are not only safe and reliable, but also built for long-term performance.

Whether you’re upgrading existing infrastructure or developing a new system, our team is prepared to guide you through every stage of implementation with a focus on quality, compliance, and efficiency.

To discuss your project or request a consultation, please contact us at:

📞 (713) 808-9072

📧 info@asi-e.com

🌐 www.asi-e.com

Partner with ASI to advance your automation goals with proven expertise and enduring results.